I don’t much like PCBs, but I like wiring ICs up even less. Up till now I’ve made boards with the toner-transfer-and-any-old-container method. The trouble is that I hate making up ferric cholride and always make the bare minimum, and during etching the concentration falls off, the rate slows, and you get poor definition and damage. So I decided to make a proper vertical etching tank, big enough to do a large board and still not run out of etchant. Casting about the shed found a large transparent dust-sheet, and I wondered about using it for the tank. With care an unpierced section could be found, and a bag was taped together:

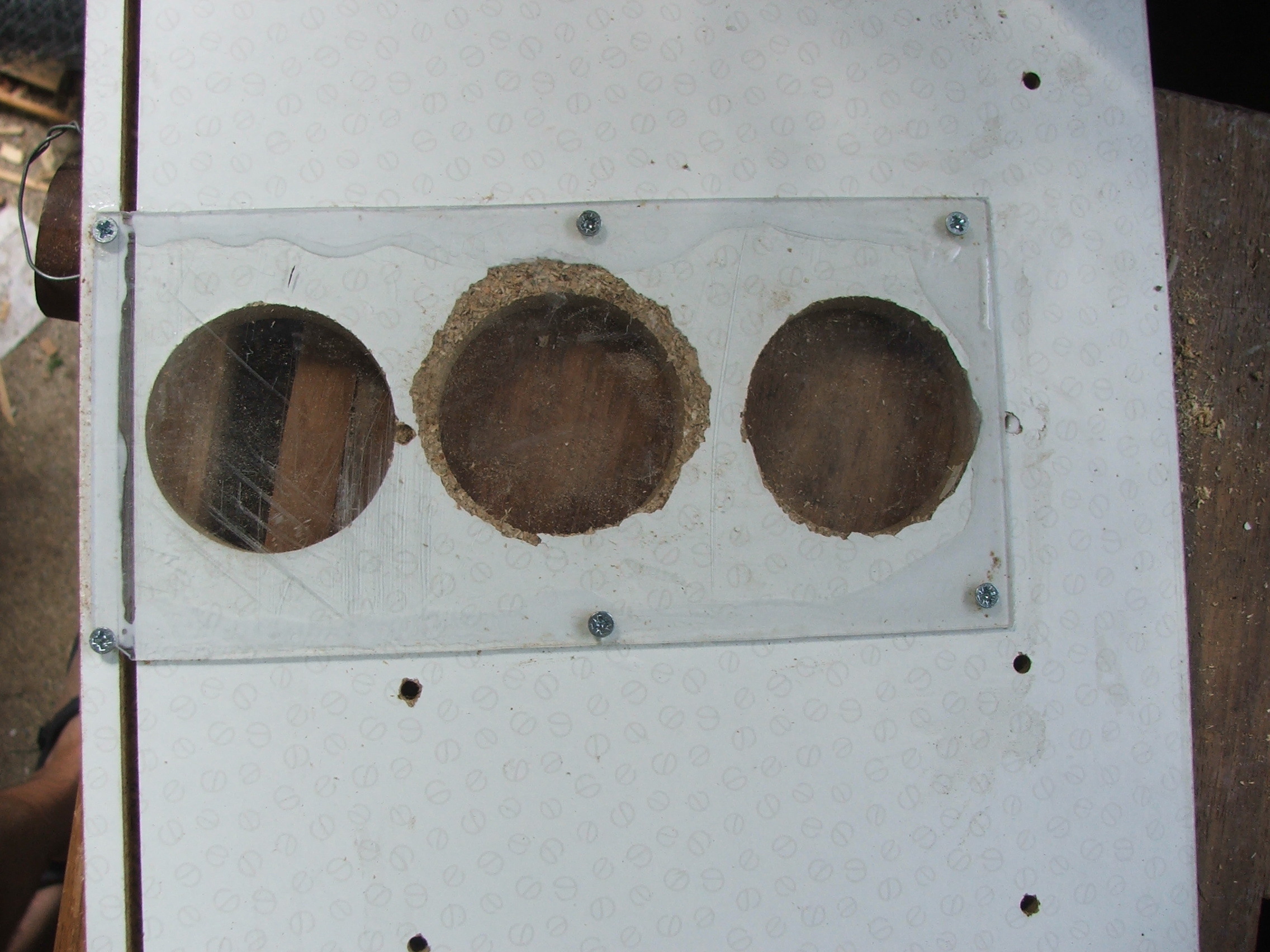

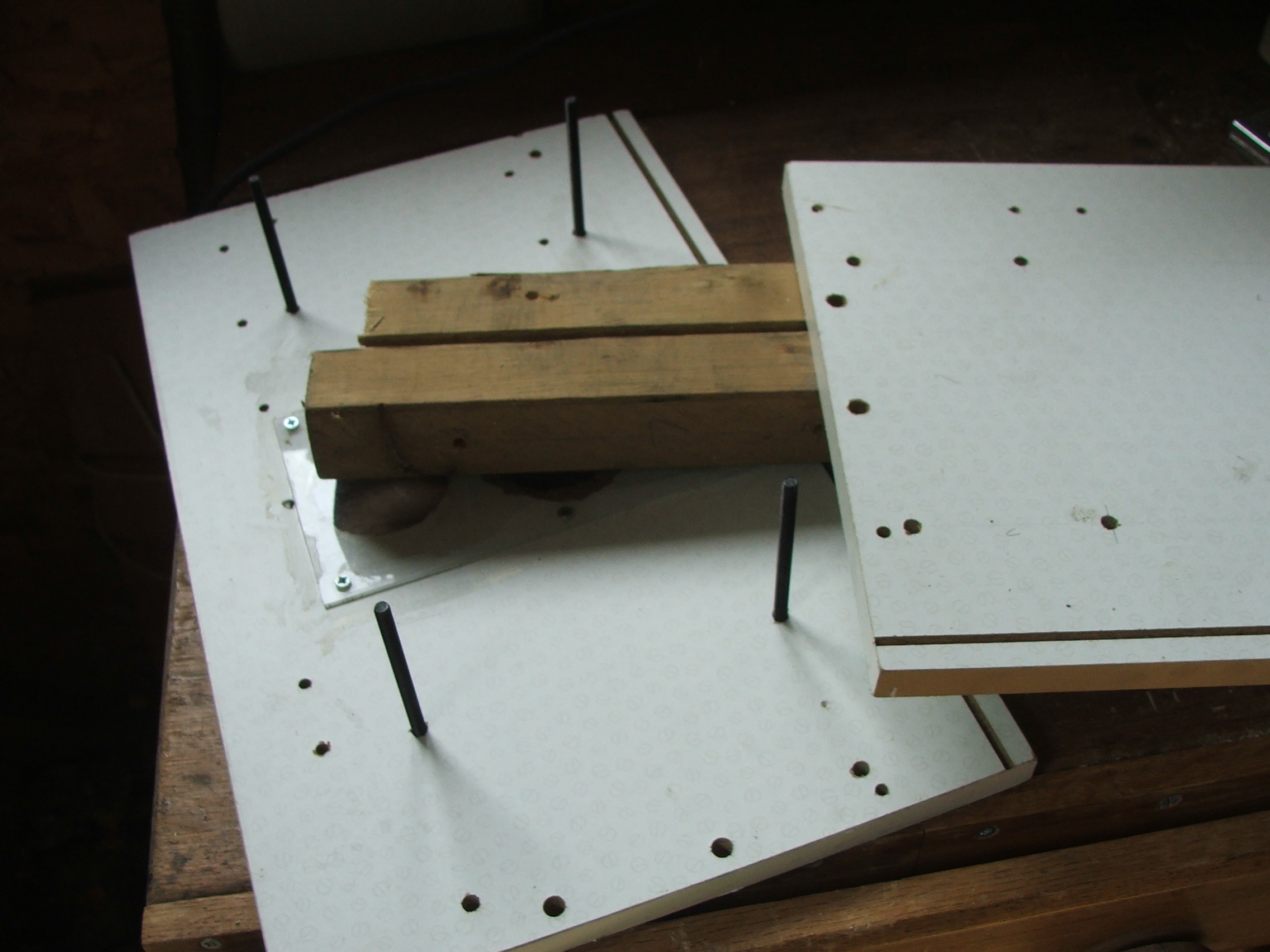

And a chipboard frame, with viewing window, made for it:

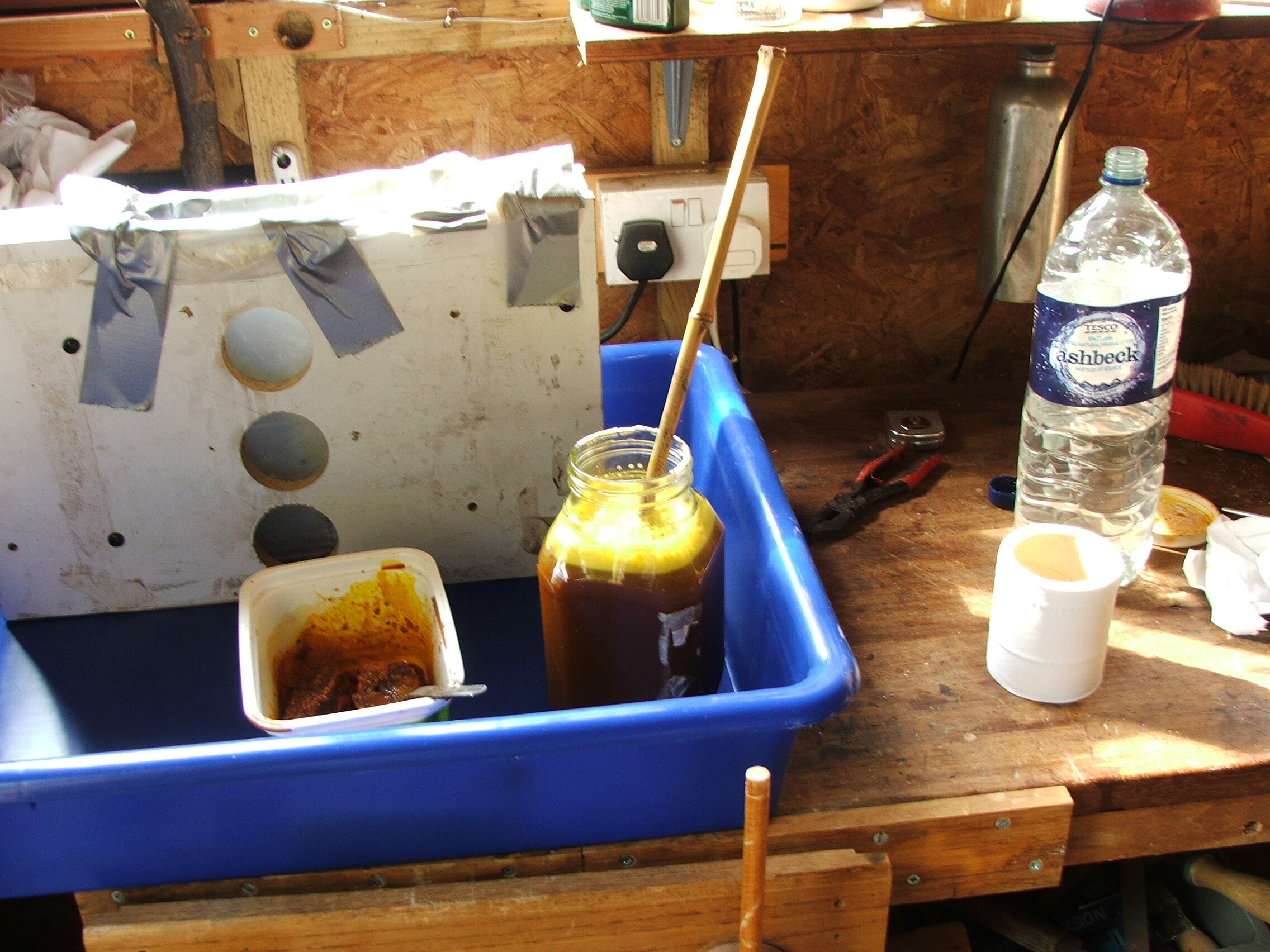

It took a while to work out how to compress the seals in the frame to keep it watertight, but in the end it was tested successfully. Then to make up enough ferric cholride for a tank of this size: a messy business when the pellets have been stored in a shed and turned into one water-glued lump. I had to cut the case apart with a hacksaw and break up the solid lump—and all this without spilling any or getting it on clothes. But in the end it worked:

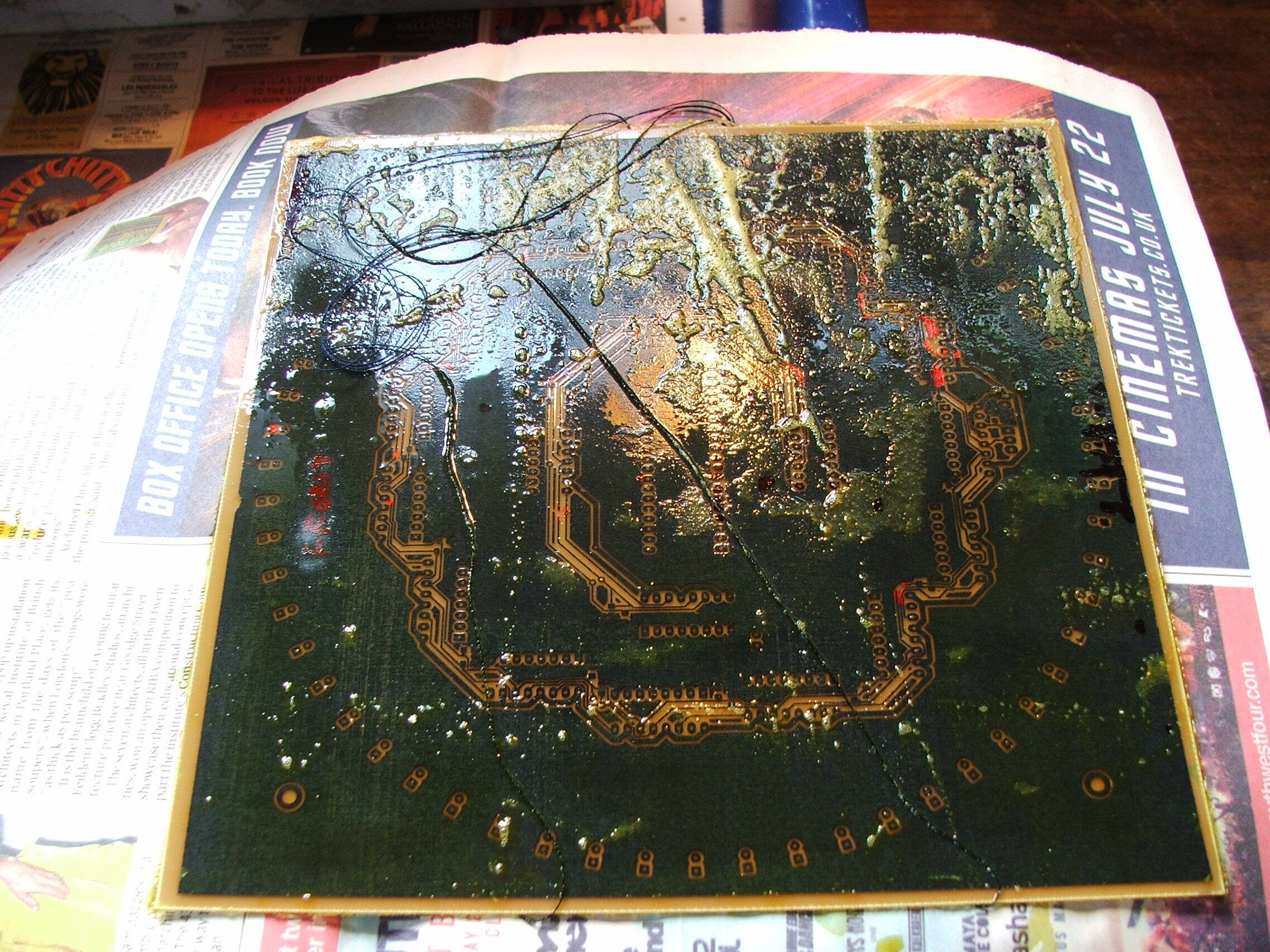

And etched a large double-sided board, very well under the circumstances:

Now, how to get the etchant out? Pouring it was out of the question. I had a little siphon I made as a child for refilling ink bottles, and it got rid of some of it:

But not much more than that. A larger head was needed, and a longer siphon. This tube is cat-5 outer insulation, started with a syringe in the end. With care you can keep it off your hands, but the stuff isn’t that dangerous:

And there we are. I do think syphons are incredible: every time I see one in action I wonder at this apparent free energy making water flow uphill.